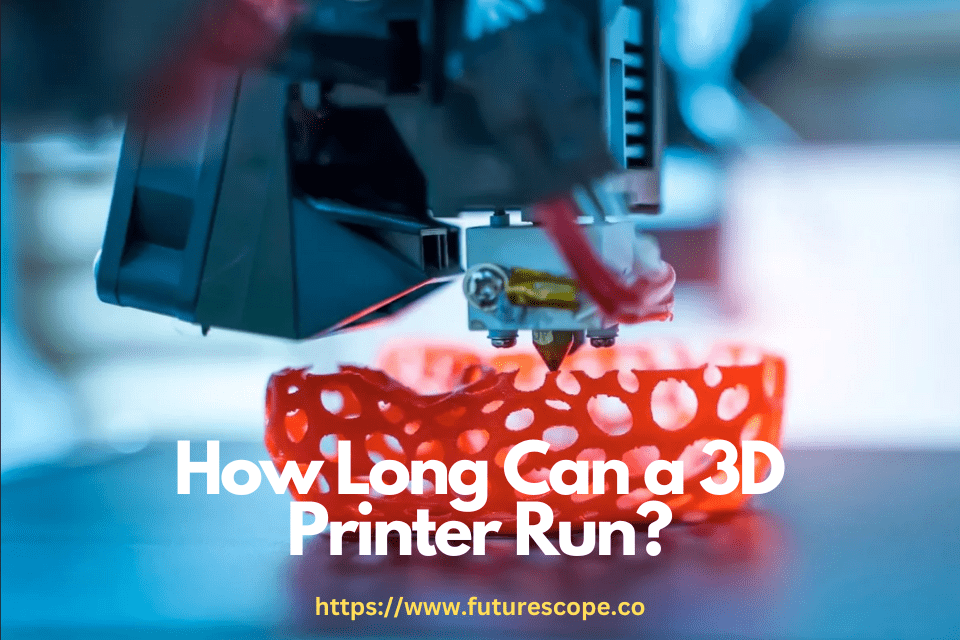

A 3D printer can run continuously for 200+ hours if maintained properly. However, very long prints increase the risk of failures.

3D printing technology has revolutionized manufacturing, enabling hobbyists and professionals alike to bring complex designs to life. With advancements in printer reliability, enthusiasts often wonder about the marathon capabilities of their machines. The duration a 3D printer can operate non-stop ties directly to the quality of the printer, regular maintenance, and the complexity of the print job.

High-end printers crafted with endurance in mind can sustain lengthy print tasks with fewer hiccups, while budget models may require more frequent supervision. Users aiming to undertake extended printing sessions must consider factors such as the stability of the power supply, the durability of printer components, and the potential for overheating, which could compromise print quality and machine longevity. Ensuring your setup meets the job’s demands is key to successful long-term printing endeavors.

Factors Influencing 3D Printer Runtime

When diving into the world of 3D printing, it’s vital to understand how long your 3D printer can run. The runtime of a 3D printer depends on several factors that can affect the outcome and efficiency of your prints. Let’s explore these factors to ensure you get the best results from your 3D printing experience.

Printer Model And Specifications

Different 3D printers come with varying capabilities. Printer model and specifications play a crucial role in determining runtime. High-end models equipped with advanced cooling systems can run for extended periods, while basic models might need more frequent breaks to prevent overheating. Some key specifications influencing the runtime include:

- Printer size: Larger printers may handle longer print jobs.

- Speed: Faster printers accomplish tasks quickly but may need to cool down sooner.

- Temperature control: Printers with better thermal management have less downtime.

- Durability: Sturdier models are built for longer usage cycles.

Material Requirements

The type of material you use is another key factor. Each material requires specific temperatures and handling times. Materials such as PLA are easier to work with and require less time to cool. In contrast, materials like ABS need higher temperatures and might extend the printer’s runtime. Consider the following materials:

| Material | Temperature | Cooling Time |

|---|---|---|

| PLA | Lower | Short |

| ABS | Higher | Long |

Print Job Complexity

Your print job’s complexity significantly impacts runtime. Simple designs with fewer details are finished faster than complex ones with intricate patterns or support structures. A few points on complexity include:

- Larger prints with more layers take more time.

- Intricate details slow down print speed for precision.

- Support structures for overhangs add to print duration.

Maintenance And Care For Extended Use

Unlocking the full potential of a 3D printer goes beyond just using it. Maintenance and care are crucial to ensure your machine runs smoothly over long periods. This guide walks through essential steps to keep your 3D printer in top shape.

Regular Cleaning Routines

Cleanliness is a key factor in the longevity of a 3D printer.

Implement a consistent cleaning schedule to prevent buildup that can lead to jams and quality issues.

- Wipe down the build plate after each use.

- Clear out any remaining filament from the nozzle.

- Use a soft brush to remove debris from moving parts.

Part Replacement And Upgrades

Over time, parts wear out.

Regular inspection and timely replacement prevent breakdowns.

| Part | Check Frequency | Signs of Wear |

|---|---|---|

| Belts | Every 3 months | Slackness, tears |

| Nozzles | Every 6 months | Diameter widening |

Consider upgrading parts for better performance and durability.

Avoiding Common Wear And Tear Issues

Prevention is better than cure.

Understand common issues to safeguard your printer.

- Keep firmware updated to fix bugs and improve functionality.

- Use recommended filament types to reduce extruder strain.

- Avoid abrupt stop-starts; they wear out motors.

By following these steps, ensure your 3D printer operates effectively for years to come.

Real-world 3D Printing Projects Duration

Embarking on a 3D printing project sparks a flurry of questions. A common inquiry: How long can a 3D printer run? Project duration varies widely in the realm of 3D printing. Factors affecting duration range from complexity to size. This exploration delves into typical timelines for 3D prints, tailored to the scale and purpose of the project. Understand project timeframes to plan effectively and harness the full potential of 3D printing technology.

Small-scale Hobbyist Prints

Hobbyist 3D printing often involves smaller, less intricate objects. These can include:

- Figurines: Ranging from 1 to 3 hours.

- Phone Cases: Approximately 4 hours.

- Jewelry: Between 2 to 6 hours.

Hobbyist printers are usually designed for shorter runs. They can reliably operate for about 30 continuous hours. Always check manufacturer guidelines to ensure printer longevity.

Industrial-grade Manufacturing Tasks

Industrial 3D printers tackle more daunting tasks. Duration for industrial projects may entail:

| Project Type | Duration |

|---|---|

| Prototypes | 24 to 72 hours |

| Functional Parts | 48+ hours |

| Large Assemblies | Varies greatly |

These robust machines are built for endurance. They can often run non-stop for several days on robust projects.

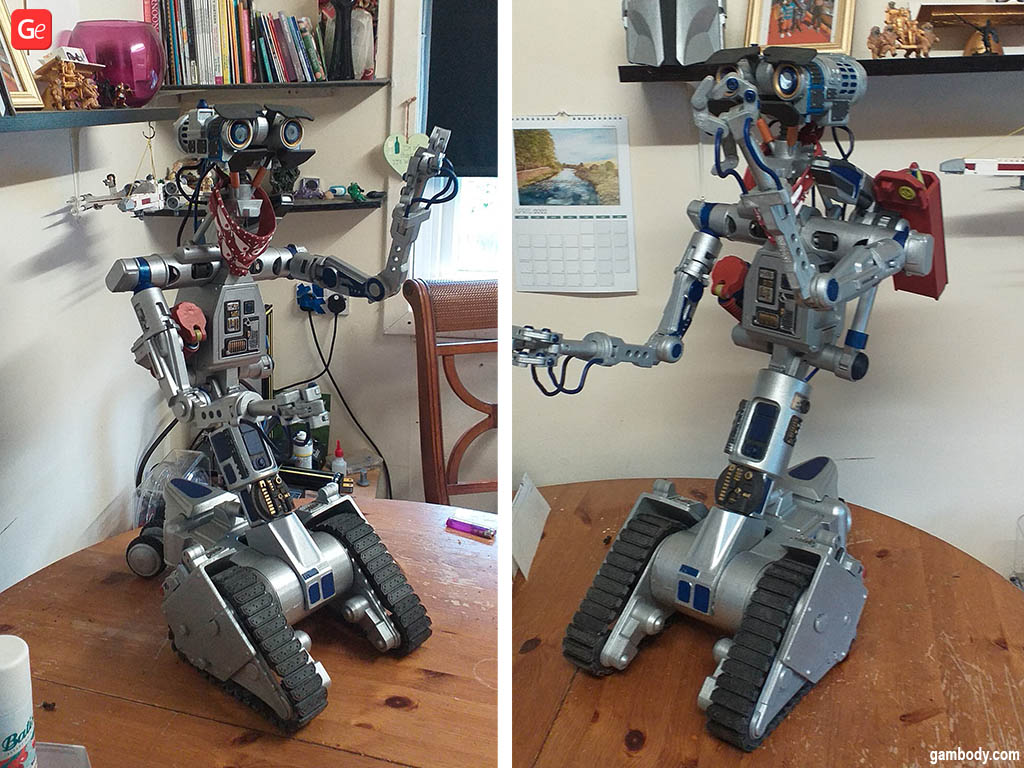

Record-breaking Marathon Prints

Some prints challenge the limits and set records. Marathon prints involve:

- Art Installations: Could stretch beyond a week.

- Architectural Models: Several consecutive days.

- Custom-designed Furniture: Over a hundred hours.

Record prints push machines to new heights. One printer ran for over 100 days creating a full-size house.

Safety And Best Practices For Long Print Runs

When diving into the wonders of 3D printing, safety and best practices should never take the back seat, especially during long print runs. These help maintain your printer’s health and safety. Let’s explore how to tackle extended printing sessions while keeping risks at bay.

Monitoring Temperature And Ventilation

Keeping the temperature in check is critical for both printer performance and safety. Here’s what to consider:

- Regular Checks: Monitor your printer’s temperature during long runs.

- Adequate Cooling: Ensure active cooling systems are functioning correctly.

- Proper Ventilation: Use printers in well-ventilated areas to avoid fume buildup.

Ventilation fans should extract any harmful emissions, reducing health risks.

Ensuring Reliable Power Supply

Consistent power is essential for uninterrupted 3D printing. Any fluctuation could be detrimental. Follow these tips for a stable supply:

- Surge Protectors: Protect your equipment from power spikes with surge protectors.

- Uninterruptible Power Supplies (UPS): A UPS can keep your printer running during short outages.

- Regular Inspections: Check your power cables and outlets for wear and tear.

Software For Interrupted Print Recovery

Unexpected interruptions during long prints can be frustrating. Equip yourself with a plan to rescue these prints:

- Recovery Features: Choose printing software that offers recovery options after power loss.

- Save Progress: Use software that frequently saves printing progress automatically.

- Manual Notes: Keep a log of your print progress in case of software failure.

This way, you don’t have to start from scratch should you encounter a hiccup.

Frequently Asked Questions For How Long Can A 3D Printer Run?

How Long Can You Leave A 3D Printer Running?

You can leave a 3D printer running for the duration of the print job, which can range from a few hours to several days. Ensure you follow the manufacturer’s safety guidelines and check for any potential hazards periodically.

Is It Bad To Run A 3D Printer 24 7?

Running a 3D printer continuously can lead to wear and tear, requiring more frequent maintenance and potentially reducing the printer’s lifespan. Ensure safety measures are in place and monitor printer condition regularly.

How Many Hours Can You Run A 3D Printer?

A 3D printer can typically run continuously for 20 to 100 hours, depending on the model, print complexity, and manufacturer’s recommendations. Always monitor for safety and performance.

How Long Can A Ender 3 Run?

An Ender 3 3D printer can run continuously for over 200 hours, but regular maintenance is recommended to ensure optimal performance and longevity.

Conclusion

Summing up, the endurance of a 3D printer hinges largely on its model and maintenance. Proper care can extend run times significantly, ensuring long-lasting performance. It’s crucial to consult your manufacturer’s guidelines to optimize usage. Remember, caring for your printer is key to maximizing its potential and bringing your creative visions to life.