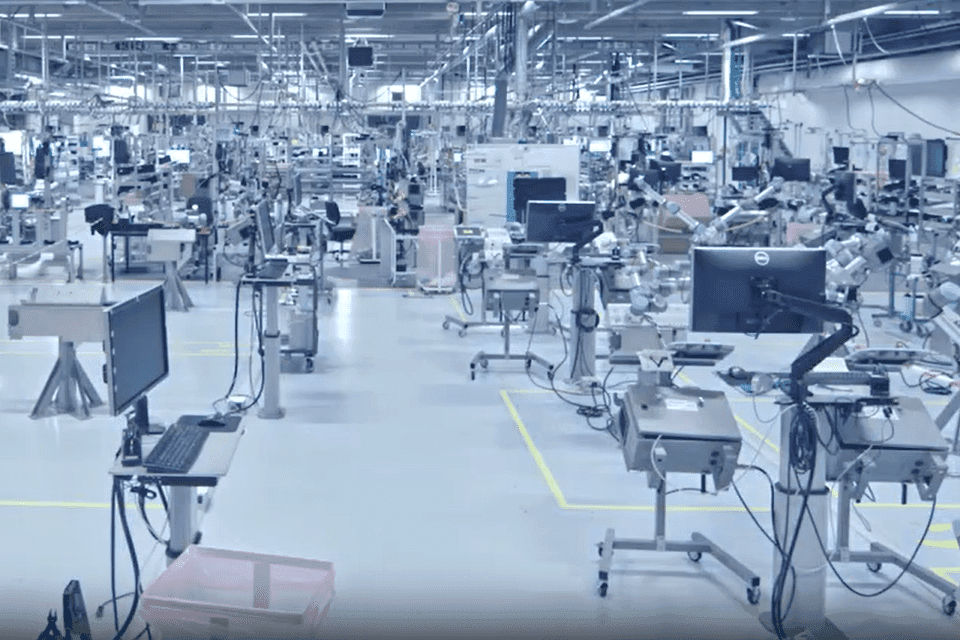

Cleanroom manufacturing is a critical aspect of various industries, including pharmaceuticals, biotechnology, and electronics. In these environments, maintaining high levels of cleanliness and precision is paramount. Enter collaborative robots, or cobots—an innovative solution designed to enhance efficiency and productivity. This article explores the transformative impact of cobots in cleanroom settings, detailing their benefits, applications, and future trends.

Understanding Cleanroom Manufacturing

Cleanrooms are controlled environments designed to minimize contamination. They adhere to strict standards, classified under ISO classifications that dictate particle levels and microbial contamination. For example, an ISO 5 cleanroom permits no more than 3,520 particles per cubic meter, making it essential for industries where even minute contamination can lead to significant issues. The air quality, temperature, and humidity must be meticulously controlled to ensure that products, particularly sensitive items like pharmaceuticals or microelectronics, are produced without contamination.

While cleanrooms provide the ideal conditions for manufacturing sensitive products, they also come with challenges. The processes are often labor-intensive, requiring meticulous handling and assembly of components. Additionally, maintaining the stringent conditions of a cleanroom can be costly, both in terms of infrastructure and operational expenses. As manufacturers seek to optimize efficiency while adhering to strict cleanroom protocols, innovative solutions are required.

The Role of Cobots in Cleanroom Manufacturing

Collaborative robots, commonly known as cobots, are specifically engineered to function alongside human operators. In contrast to conventional industrial robots, which tend to be bulky and necessitate safety barriers, cobots are smaller and come with built-in sensors that enable them to work safely near people. Their user-friendly programming allows for rapid adjustments to a variety of tasks. This adaptability is especially advantageous in cleanroom settings, where procedures may need to be frequently modified.

Types of Tasks Performed by Cobots

Cobots excel in performing repetitive and precision-oriented tasks in cleanrooms. Some common applications include:

- Material Handling: Cobots can efficiently move materials from one point to another, reducing the physical strain on human workers and enhancing workflow.

- Assembly Tasks: In environments where precision is critical, cobots can perform assembly tasks with high accuracy, ensuring that products meet strict quality standards.

- Quality Control Inspections: Cobots can be equipped with advanced sensors and cameras to inspect products for defects, ensuring that only items that meet stringent criteria proceed through the manufacturing process.

For those interested in exploring the capabilities of collaborative robotics further, companies like Universal Robotics offer a range of solutions tailored to meet the demands of cleanroom environments, setting the stage for a new era of manufacturing efficiency.

Benefits of Cobots in Cleanroom Manufacturing

One of the most significant advantages of integrating cobots into cleanroom manufacturing is the enhancement of efficiency. Cobots can work continuously without fatigue, which helps to reduce cycle times and improve throughput. For instance, tasks that would take a human operator a significant amount of time can be completed in a fraction of that time by a cobot, leading to a more streamlined production process.

Increased Precision and Quality

Cobots are programmed to perform tasks with remarkable consistency, significantly reducing human error. In cleanroom manufacturing, where precision is crucial, this consistency can lead to higher product quality and reduced waste. By performing repetitive tasks with a high degree of accuracy, cobots help ensure that products meet strict regulatory and quality standards.

Flexibility and Scalability

Cobots offer manufacturers a unique level of flexibility. They can be quickly reprogrammed to handle different tasks, allowing for efficient adaptations in production lines as demand changes. This scalability is essential in industries that experience fluctuating production needs, as it allows manufacturers to respond swiftly without incurring significant downtime or additional costs.

Improved Worker Safety and Comfort

By automating strenuous and repetitive tasks, cobots contribute to a safer work environment. Human workers can focus on higher-value activities, such as decision-making and problem-solving, while cobots handle the more physically demanding aspects of production. This collaboration not only reduces the risk of workplace injuries but also leads to increased job satisfaction among workers.

Challenges and Considerations

While the benefits of cobots are clear, integrating them into existing cleanroom processes can present challenges. Manufacturers must ensure that the cobots are compatible with their systems and that they meet all regulatory requirements. Additionally, the setup and calibration of cobots can be time-consuming and require specialized knowledge.

To fully realize the potential of cobots, companies must invest in training programs for their workforce. Employees need to be educated on how to work alongside cobots safely and effectively. This investment not only facilitates a smoother integration process but also enhances the overall skill set of the workforce.

The initial investment in cobots can be significant. Manufacturers must conduct thorough cost-benefit analyses to determine the long-term financial advantages of adopting this technology. While the upfront costs may seem daunting, the potential for increased efficiency, reduced labor costs, and enhanced product quality often justifies the investment.

Conclusion

Cobots represent a significant advancement in cleanroom manufacturing, offering enhanced efficiency, precision, and flexibility while improving worker safety. As industries increasingly recognize the benefits of collaborative robotics, the future looks promising for the integration of these innovative machines in cleanroom environments. Manufacturers who embrace this technology will not only optimize their production processes but also pave the way for future innovations in the industry.