No, you cannot turn a regular inkjet printer into a functional 3D printer. Inkjet printers lack the necessary mechanisms to print 3D objects.

Converting of an inkjet printer into a 3D printer isn’t practical or feasible due to fundamental differences in their technologies. An inkjet printer operates by depositing liquid ink onto paper, whereas a 3D printer builds objects layer by layer using materials like plastic or resin.

The complex mechanics and software for 3D printing vastly differ from the simple paper and ink handling of inkjet printers. Despite sharing the term ‘printer,’ both serve distinct purposes in the digital creation and physical realm. This distinction is essential for individuals and businesses exploring printing solutions for various applications. Understanding these machine capabilities ensures effective investment in technology that meets specific printing needs.

From Paper To Plastic: The Possibility Of Transforming Inkjet Printers

Imagine turning your everyday inkjet printer into a machine that prints 3D objects. It seems like a leap from thin air to solid creations. Yet, is this transformation really possible? Explore the fascinating world where conventional printing meets 3D innovation.

Inkjet printers create images on paper by depositing tiny droplets of ink. 3D printers build objects layer by layer, using various materials like plastic. Despite the differences, both technologies share a common goal: precision and detail.

Let’s examine how they compare:

| Inkjet Printing | 3D Printing |

|---|---|

| 2D prints on paper | 3D prints from plastic, metal, more |

| Uses ink cartridges | Uses filaments or resin |

| High-resolution color prints | Prints single-color objects |

For an inkjet to become a 3D printer, certain changes are a must. 3D printers have unique components that inkjet printers lack:

- Extruder: Heats and deposits material

- Build plate: Platform where 3D objects form

- Motors: Move the extruder in 3 dimensions

- Cooling system: Prevents overheating

These parts enable a 3D printer to create real and tangible objects. An inkjet printer must undergo extensive modifications to incorporate them.

Step-by-step Transition: Inkjet To 3D

Curiosity often leads to innovation, and the idea of converting an inkjet printer into a 3D printer is no exception. This step-by-step transition takes DIY enthusiasts through an intriguing journey of transformation. A regular inkjet printer designed for printing on paper can embark on a new life, crafting three-dimensional objects. Let’s dive into the process that turns the imaginable into reality.

Modifications Required For 3D Capabilities

Transforming an inkjet printer demands significant changes. The primary task is to adapt the printer’s mechanics for 3D printing. This includes:

- Removing the ink system and making room for a filament extruder.

- Installing a 3D printer nozzle that can handle the chosen filament material.

- Attaching a heated bed to the printing platform to ensure proper filament adhesion.

- Reinforcing the printer’s framework, if necessary, to support the new hardware.

Sourcing And Assembling Materials

Material sourcing is key to a successful conversion. Here’s a checklist to get started:

- Find a suitable 3D printer extruder kit.

- Obtain a high-quality filament compatible with the extruder.

- Purchase a heated print bed that fits the printer’s dimensions.

- Ensure all electronic components, like stepper drivers, are available.

Assembling these materials requires patience and precision. Follow each component’s unique installation guide carefully.

Firmware And Software Adjustments

Finally, the printer’s brain needs an update. Firmware and software configurations are essential steps: Firmware Replace the printer’s original firmware with one suitable for 3D printing, like Marlin or Repetier. Slicing Software Install software to convert designs into printable formats, such as Cura or Slic3r.

Test multiple prints to calibrate and fine-tune the settings for optimal 3D printing performance.

Challenges And Limitations Of Conversion

Converting an inkjet printer into a 3D printer is not a simple task. It involves overcoming various challenges and understanding the technical limitations. Let’s explore some of these obstacles.

Precision And Accuracy Considerations

Transforming an inkjet printer into a 3D printer requires high precision. The original design isn’t meant for 3D printing tasks. This can cause issues with the final print quality. Consider these points:

- Inkjet printers lack the movements needed for accurate 3D printing.

- Mechanical components need upgrades to match 3D printing standards.

- Software modifications are crucial to control the new outputs.

Material Compatibility And Constraints

The materials that a 3D printer uses differ greatly from inkjet cartridges. Adapting an inkjet printer to work with these new materials involves:

| Material | Constraints |

|---|---|

| Thermoplastics | Require high temperatures |

| Resins | Need UV curing |

| Metallic powders | Involve laser sintering |

Practical Use Cases And Innovations

Innovation thrives where curiosity and experimentation intersect. The realm of printing technology witnesses a fascinating blend of both. Can we turn an inkjet printer into a 3D printer? This idea isn’t just a shot in the dark. Numerous practical use cases and innovations have emerged from toying with this very question.

Successful Projects And Case Studies

Tales of success in the inkjet-to-3D printing landscape serve as a beacon for potential. These projects showcase what’s achievable with some creativity and technical know-how:

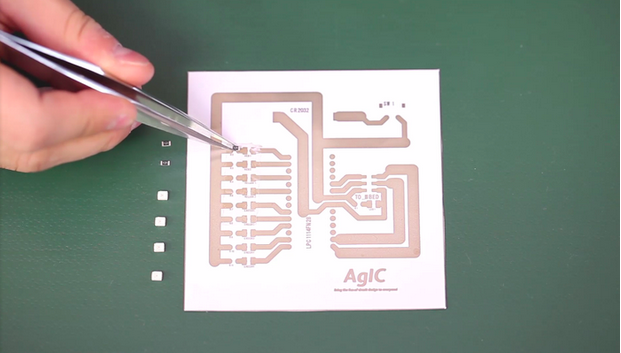

- DIY 3D Printer Modifications: Enthusiasts have converted old inkjet printers by adding extruders and new firmware, leading to unique, low-cost 3D printing solutions.

- Academic Explorations: Universities have developed modified inkjet printers capable of laying down layers of biomaterial, pushing the frontiers in bio-printing.

- Startup Innovations: Startups have repurposed inkjet technology to print with materials beyond traditional filament, from food to metal, expanding 3D printing applications.

Future Prospects: Inkjet To 3D Evolution

The transformation of inkjet printers into 3D printing devices is not just a possibility but an unfolding reality. The future holds promising prospects:

- Greater Material Versatility: Expect to see inkjet printers handle a diverse array of materials, making personalized manufacturing accessible.

- Refined Precision: As technology advances, these printers will achieve finer details, equating to higher resolution in 3D printed objects.

- Enhanced Sustainability: Repurposing inkjet printers provides an eco-friendly solution by reducing electronic waste and promoting recycling.

Frequently Asked Questions On Can I Turn An Inkjet Printer Into A 3D Printer?

Can Inkjet Printers Create 3D Objects?

Traditional inkjet printers are not designed to create 3D objects. They lack the necessary hardware to extrude and manipulate materials in three-dimensional space.

What’s Needed To Convert Inkjet To 3D?

To convert an inkjet printer to a 3D printer, substantial modifications are required including a new extruder head, motion control hardware, and 3D printing software.

Are DIY 3D Printer Kits Available?

Yes, various DIY 3D printer conversion kits exist to modify traditional printers, though compatibility and effectiveness vary widely.

How Does 3D Printer Conversion Work?

3D printer conversion involves replacing the ink system with a 3D printing extruder, upgrading firmware, and installing components for movement along the x, y, and z-axes.

Conclusion

Transforming an inkjet printer into a 3D printer presents intricate challenges. It’s not a straightforward process but an intriguing experiment for tech enthusiasts. While feasible, the practicality and cost-effectiveness require thorough evaluation. For adventurous makers, this project could pave the way to unique, custom 3D printing solutions.

Pursue cautiously and embrace the learning curve.